Active worldwide

Wayss & Freytag turns into a globally active group of companies. New business fields are added: environmental technology, building preservation and consulting. In shield technology, EPB shields and solid rock TBMs are used besides hydro and mix-shields. Shield technology in waterbearing loose soils creates new possibilities for tunnel construction.

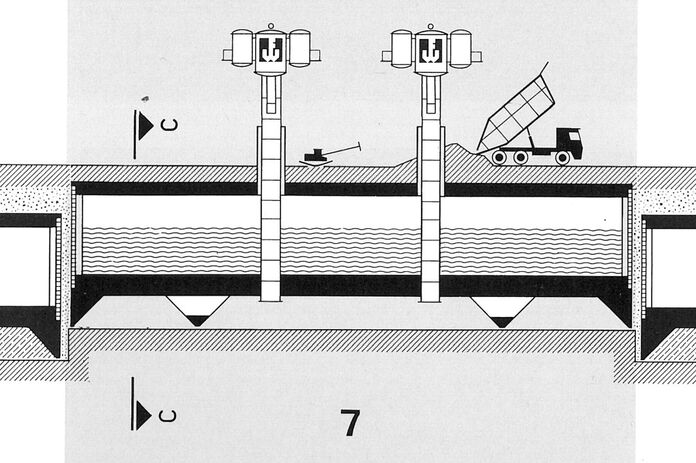

An immersed tunnel in Amsterdam

An immersed tunnel in Amsterdam

For the construction of Amsterdam Metro Wayss & Freytag prepared a caisson solution as their special proposal, for which the contract was awarded in 1970. The design was based on the experience the company had gained previously in Berlin with compressed-air foundation works for the metro construction lots H 102 and G 19. The first section, from the central railway station under Weeserplein up to Waterlooplein, was built between 1970 and 1976. The opening ceremony took place on October 16, 1977.

Earth-models served as formwork for the working chambers. This method had first been successfully tested by W&F in 1953 during the construction of the pumping station Duisburg-Stockum – Alte Emscher. By arrangement of intermediate cutting edges according to a W&F patent of 1933, it was possible to increase the stability and achieve a high precision in a lateral position during the sinking process. W&F first used such intermediate or bearing cutting edges in 1935 during the construction of the sea lock in Ostende. To remove the ground during the sinking process, fixed mounted jet mud guns were used. This epoch-making method was also developed by Wayss & Freytag and first introduced in 1932 during the extension of the Eastern mole in Dunkirk.

After they were sunk, the 40 m long caissons were connected to each other by watertight expansion joints. Special attention had to be paid to the concrete mixture, since the structure was not only exposed to high compressive stresses, but also had to be watertight and, during the construction phase, it was also exposed to high thermal stresses. To keep down the concrete temperatures, pipes placed inside the caisson were used for cooling.

The "Ginnheimer Spargel"

The "Ginnheimer Spargel"

Wayss & Freytag AG built the telecommunication tower in Frankfurt, unofficially also known as „Ginnheimer Spargel“ (Ginnheim asparagus), in a joint venture under their technical leadership, after they had gained respective experience during the construction of high chimneys and various other telecommunication towers. At the time of its completion, this telecommunication tower, with its height of 331 m, was the second highest in Germany and only beaten by the tower at Alexanderplatz in East Berlin, on the other side of the Berlin wall.

The tower in Frankfurt is based on a ring foundation with a diameter of 48 m and a thickness of 18 m. The shaft diameter is 20 m at the bottom and 5.60 m at the tower head, whereas the thickness of the shell, at 55 cm, is nearly constant throughout the entire height. At a height of 211 m, a six-floor pulpit starts which reaches up to an altitude of + 237 m. The pulpit has a maximum outer diameter of 57.30 m. Its floors were built using the steel composite construction method.

The tower shaft and the shaft for the elevator and the emergency staircases inside the tower were built simultaneously with climbing formwork. By prestressing the outer formwork, it was possible to achieve an excellent exposed concrete structure. The futuristically designed building at the tower base, in which the operational building, an own power plant and the representative rooms for the public are located, is also impressive.

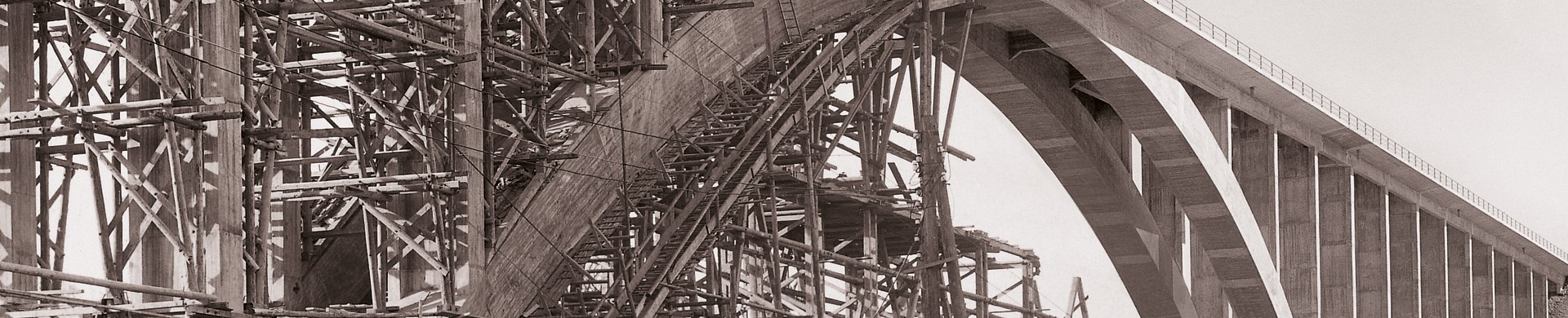

Higher than the Freiburg Cathedral

Higher than the Freiburg Cathedral

With a height of 185 m above valley floor, the Kochertal Bridge near Geislingen is the highest bridge in Germany and, after the Viaduc de Millau in France, the second highest in the world. The prestressed concrete structure, which was built under the technical leadership of Wayss & Freytag AG between 1977 and 1979, crosses the A6 motorway between Heilbronn and Nuremberg and is 1,128 m long.

The designers chose a single-cell box as a 31 m wide superstructure for both directions, which was carried out using the cantilever construction method. Two cantilever carriages advanced from a pillar to the middle of the panel and were then transferred to the next pillar head. The short construction period of only 22 months required simultaneous construction from both abutments.

In some places, the ground had to be improved by means of cement injections for the foundation of the pillars in the rugged shell limestone. In other parts, 45 m deep shafts had to be sunk to reach stable ground. The pillars were built using climbing formwork. For stabilisation reasons, the four pillars in the middle had to be fixed to the superstructure, so that in longitudinal direction of the bridge a framework was formed as statical system.

In Sable d’Osticourt

In Sable d’Osticourt

Lot 3 of Lille Metro connects the stations „Petite Chapelle“ and „Maison des Enfants” over a length of 3,540 m. The tunnel tube, which was driven with a mixshield TBM, has an outer diameter of 7.70 m with a minimum cover of 10 m. Besides the tunnel, six stations had to be built using the top-down method. The construction works started at the beginning of 1985 and ended in spring of 1988.

The mixshield, which was developed by Wayss & Freytag and built by Herrenknecht in Schwanau, works like a hydroshield with a liquid-supported tunnel face. The pressure of the liquid is controlled by pressurized air. The cutting wheel is arranged in such a way that it can be refitted for transportation of dry material. The soil which is loosened by the cutting wheel is transported hydraulically. Despite the fact that the ground in Lille varies from soils like chalk, marl, coarse clay to sand (Sable d’Osticourt), the shield drive was carried out accurately and without problems.

The tunnel tube has a single lining consisting of 35 cm thick and 1.20 m wide concrete segments. Each ring consists of seven concrete segments, each slightly longer than 3.0 m, and one wedge-shaped keystone. To keep to the appropriate direction while driving bends to the left or right, conical rings were installed. The tolerance of each concrete segment was ± 0.5mm.

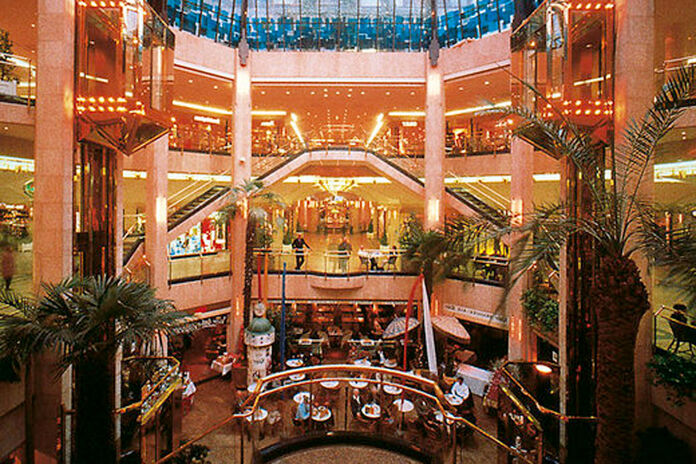

At the "Königsallee" in Dusseldorf

At the "Königsallee" in Dusseldorf

Between 1985 and 1987, the city-centre Kö-Galerie was built in a joint venture in Düsseldorf’s most expensive shopping street. It consisted of four deep basement floors, three shopping floors and five office floors. Due to the short construction period and the close proximity of neighbouring buildings, the so-called “top-down method” was used in Germany for the first time (Düsseldorfer Deckel - Düsseldorf cover slab). In this construction method, a concrete roof slab is built at road level on an earth model and the construction works are then simultaneously carried out using the mining technique downwards and conventionally upwards. This top-down method has two decisive advantages which compensate for the additional costs: settlements of neighbouring buildings are close to zero and the reduction in construction time is enormous, in the case of Kö-Galerie it was 35%.

Before concreting the roof slab, diaphragm walls were built up to the level of watertight tertiary layers. After that the prefabricated composite steel supports (primary columns) were installed to bear the loads of the buildings in liquid-supported boreholes. Each further slab that was concreted below the upper roof slab on the earth model served as reinforcement for the diaphragm walls and as the roof slab for the next basement floor.

Further details:

- 6,500 m² plot area

- 240,000 m³ building volume

- 9,400 m² diaphragm walls th = 80 cm

- 16.5 MN maximum column loads

The Rheinufer Tunnel in Dusseldorf

The Rheinufer Tunnel in Dusseldorf

Between 1990 and 1993, the Rheinufer Tunnel (tunnel on the banks of the River Rhine) was built to provide the people of Düsseldorf with traffic free access to the banks of the river Rhine and traffic calming for the neighbouring residential areas. The tunnel, which was built in a joint venture, relocates the street „Rheinuferstraße“ underground for a length of 1,928 m. The groundbreaking ceremony took place on March 15, 1990 and the road was opened to traffic in the presence of a large proportion of the population on December 15, 1993.

The south portal is situated at Lahnweg, in the district Unterbilk near Rheinturm (Rhine tower) and Landtag (state parliament). The north portal is in the historic centre south of Oberkassel Bridge. To take into account cramped conditions at the river Rhine, the tunnel had to be executed on two levels in the area of the historic centre, which required a 17 m deep excavation. First, the upper tunnel was completed protected by diaphragm walls and then the lower tube was carried out using the conventional (mining) technique with compressed air. To avoid building settlements, extensive underpinnings of the neighbouring buildings were required by means of high-pressure grouting.

The building on top of the south portal, the Düsseldorf Stadttor - a 19 floor tower block and office of the state premier of North Rhine Westphalia is considered to be a technical highlight within this Düsseldorf structure of the century.

Further details:

- 600,000 m³ excavated earth

- 235,000 m³ concrete

- 22,000 t reinforcing steel

- 55,000 cars / day

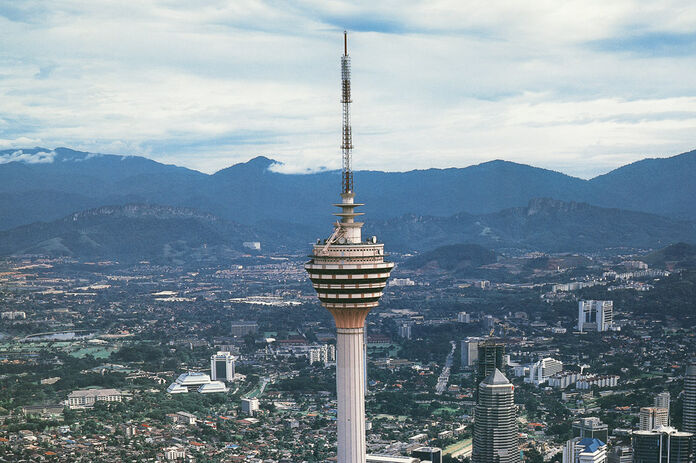

The Kuala Lumpur Tower

The Kuala Lumpur Tower

The telecommunication tower in Kuala Lumpur, Malaysia, which was built by Wayss & Freytag between 1992 and 1996, with its height of 421 m, is the fourth highest reinforced concrete tower in the world. The tower has a 17 m high conical foundation with the biggest diameter of 54 m on weathered claystone. The outer parabolic shaft, which had been concreted using the slip form method, is 317 m high and has a diameter of 24.50 m at the base and 13.60 m at the head. Wall thicknesses vary from 1.40 m at the base to 60 cm at the top. The inner shaft bearing the antenna mast was concreted up to a height of 333 m.

At a height of 270 m, there is a six floor tower head with a maximum diameter of 50 m and a total area of 7,700 m² in which offices as well as a revolving restaurant and an observation deck are located. The adaptation of the tower head to the shaft is carried out impressively by means of prefabricated bended plates with Islamic ornaments. At the tower foot, a multi-storey touristic building with various shops, restaurants and a theatre was built, the roof construction of which extends over two floors and has an architectonically demanding design in that its curved form simulates that of a pineapple.

Further details:

- 45,000 m³ concrete

- 5,300 t reinforcing steel

- 1,300 t structural steel

- 100,000 t total weight

W & F will Dutch

W & F will Dutch

In December 1996, Hollandsche Beton Groep nv (HBG) acquired the majority of shares in Wayss & Freytag AG from AGIV. W&F was now a group company of the worldwide-operating Dutch market leader.

HBG was founded on January 18, 1902 by Dr. ir. A.C.C.G. Hemert as „Hollandsche Maatschappij tot het maken van werken in gewapened beton“ (a Dutch company for construction with reinforced concrete). Through wise expansion, acquisitions and mergers, the company had with its early foreign branches in Chile (1904), East India (1910) and later around the globe, but above all with its dredging business, turned into a large construction group. After the merger of the company „Hollandsche Beton Maatschappij nv“, which had borne this company name since 1929, with „Hollandse Constructie Groep nv“ in 1968, the new name “HBG” was introduced.

W&F was split into two independently operating companies, Wayss & Freytag Ingenieurbau AG and Wayss & Freytag Schlüsselfertigbau AG, after the acquisition by HBG in 1999. In 2006, Wayss & Freytag Schlüsselfertigbau AG merged with the associate company „Müller-Altvatter GmbH & Co KG“ to become BAM Deutschland.

The „Ritterhaus“ in Halle / Saale

The „Ritterhaus“ in Halle / Saale

In a construction period of only 20 months the Ritterhaus was built by Wayss & Freytag in Halle / Saale. This modern shopping centre replaced the long-established department store of the same name which had been situated at the same place in Leipziger Straße and which was destroyed during the final days of the war.

The new shopping centre consists of three parking floors with more than 300 parking spaces, three shopping floors with 45 shops and dining facilities as well as three office floors and one residential floor.

Because of partly dilapidated neighbouring buildings, the very high groundwater level and extremely difficult ground situation, the structure was built using the top down method (see: Kö-Galerie, 1987), whereas the diaphragm walls in the basement floors had to be built as final watertight outer walls in order to maximise the usable area. To ensure adherence to the permitted construction height, it was necessary to carry out eight of ten slab floors as prestressed flat slab floors, whereas the support grid with 12.50 x 10.0 m required high prestressing.

The foundation of the 52 supports had to be built down to a depth of 40 m in some areas, since, due to the so-called „Hallenser Marktplatzverwerfung“, the bearing ground layers, which were overlaid by brown coal, medium sands and coarse clay could only be found at this depth.

Further details:

- 5,000 m² plot area

- 145,000 m³ building volume

- 41,000 m² useable area

- 6,000 m² diaphragm walls

- 20 MN maximum support loads

The bridge over the Great Belt

The bridge over the Great Belt

The crossing of the Great Belt consists of the 6,611 m long West Bridge from Sprogø to Fünen, which was completed in 1994, and the 6,790 m long East Bridge from Zealand to Sprogø, which was built by Wayss & Freytag in a joint venture. The construction costs of approx. 2.9 billion Euro will be amortised by toll revenues over the next 30 years. The Stœrebelt crossing was opened to traffic in a grand ceremony on June 14, 1998 by the Danish Queen Margarethe.

At the time of its completion, the East Bridge was the longest suspension bridge in the world. The free span between the 254 m high pylons – the highest structures in Denmark – was 1,624 m. The superstructure of the bridge is held by two ropes with Ø 83 cm, which are anchored in 63 m high blocks of reinforced concrete. The caissons for the foundation of the pylons and the anchoring blocks were prefabricated in Kalundborg and transported to the bridge by seagoing tugs. When positioning them a tolerance of 200 mm had to be adhered to.

ICE - long distance railway station

ICE - long distance railway station

The long distance railway station in Frankfurt/Main, which was built by Wayss & Freytag in a joint venture for Deutsche Bahn AG, with approx. 20,000 passengers per day, is the largest airport railway station in Germany. The station connects the ICE high-speed train Cologne – Rhine/Main to the airport. The foundation stone ceremony took place on October 1, 1997 and on May 30, 1999 the long distance railway station was opened by the arrival of the first train, the ICE „Moritzburg“, at 5:37 am.

The long distance railway station is 660 m long and 60 m wide. Construction was carried out under complicated conditions in between the ongoing traffic of the A3 motorway and the parallel national road B43. The design is planned for a nine-floor superstructure, so that a 30 cm thick structural roof slab which supports the building (= structural slab for a possible superstructure) had to be carried out with an extremely high degree of reinforcement. The 10,000 m³ of concrete for the slab were carried out monolithically and cooled down with nitrogen because of the high temperatures in summer.

The fully glazed outer shell which gives the structure transparency, width and comfortable room temperatures is considered to be a highlight of the construction, which was designed by the Hamburg group of architects Bothe, Richter and Teherani. The glass dome is situated 15 m above the platform level, the insulation glass of the facades is held at punctiform points of contact.