First build of a hyperbolic natural draught cooling tower in Germany

In 1938, Wayss & Freytag introduced the hyperbolic natural draught cooling tower in Germany together with the machine building company Balcke, Bochum. After the construction of the large Espenhain power plant near Leipzig, until the end of the war another 20 towers of this type with an output of up to 12,000 m³/h were built in central Germany. In 1948, this tradition was continued with the construction of the first tower after 2nd World War for the Wilhelmine Victoria coal mine in Gelsenkirchen and remains a core competence until today.

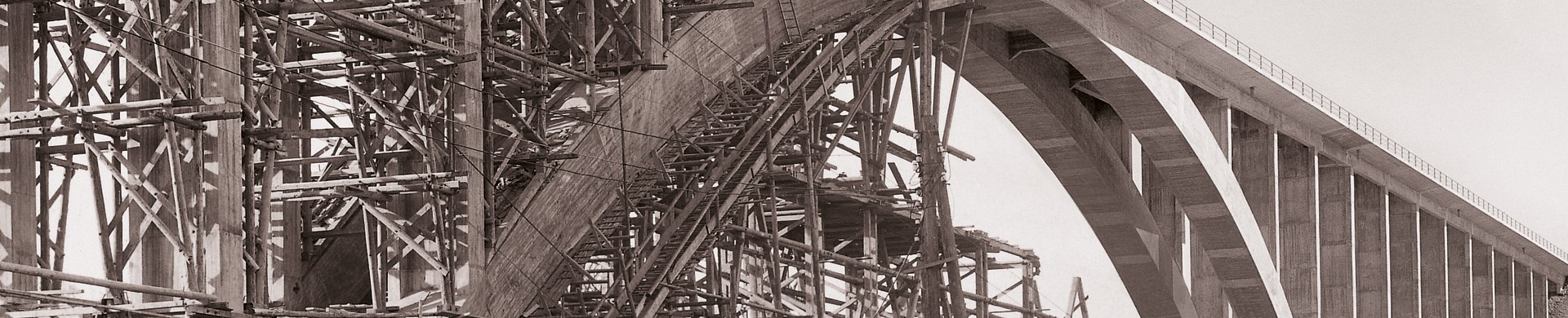

In hyperbolic cooling towers, the construction method of which never became obsolete– see Datteln power station – the chimney wall has the form of a rotating hyperboloids. The wall has to be calculated for the load cases own weight, wind and thermal stresses, whereas the load case temperature is the decisive factor for the calculation. The cooling tower shell is based on raker piles which ensure maximum aeration.

To ensure a non-deformable formwork for the chimney walls, high precision is required and above all a firm formwork. This, in particular, requires the expertise of our in-house concrete technology department, since the walls must be watertight and und acid resistant.